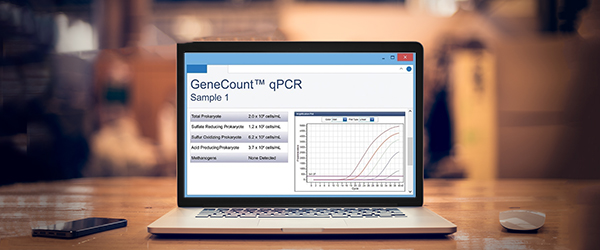

Airbus Distributes In-Service-Information (ISI) Bulletin to Evaluate BugCount® Fuel

One of the largest commercial aircraft manufacturers, Airbus, has released an In-Service-Information (ISI) Bulletin inviting its operators to trial LuminUltra’s BugCount® Fuel test kit.... Read More