Protect your product at every stage

Luminultra provides microbial certainty in every test. We give food and beverage producers the tools needed to maintain product quality and validate hygiene with precision so you can stay ahead of any potential problems.

01 A more complete picture of cleanliness

Luminultra gives food and beverage producers rapid, detailed insight into surface cleanliness. Our high-sensitivity testing helps QA teams confirm sanitation and prevent contamination.

Problem

Missed contamination signals

ATP alone can’t provide the whole picture. As ATP breaks down, important molecules like ADP and AMP - critical markers of cleanliness and early indicators of potential contamination - are left behind. Conventional ATP swabs overlook these markers, which can give QA teams a false sense of security

Solution

A more accurate view of hygiene, fast

A3 by Kikkoman detects ATP, ADP and AMP with one swab and one recombinant RLU result - capturing microbial residues traditional tools miss. With 10-second results, no external calibration and in-field simplicity, QA teams get a more accurate view of hygiene, fast. Identify issues before they become large upsets with a fast, easy test that gives you the complete picture

Where this matters

- Sanitation validation on surfaces and lines

- Pre-op and post-cleaning checks

- Packaging line hygiene assurance

- Hand hygiene efficacy

- Hotspot detection in environmental zones

Explore more

02 Simplify pathogen detection

Problem

Traditional plating is slow and expensive

Traditional agar plating can be slow, messy and expensive. Available prepared media plates often require a spreader step, are prone to leaks, and demand proprietary readers, creating bottlenecks and driving up waste and cost.

Solution

Simplify with Easy Plate™

Easy Plate™ by Kikkoman simplifies microbial enumeration with pre-poured chromogenic media. No spreader required, up to 49% faster plating, and bright colony colors make counting easy. Paired with our complimentary Colony Counting software and compatible with a standard scanner - process up to 80 plates at once, at just a fraction of the cost.

Where this matters

- Routine in-house food testing

- Shelf-life assessments

- QA environmental programs

- Meat, dairy and RTE microbial enumeration

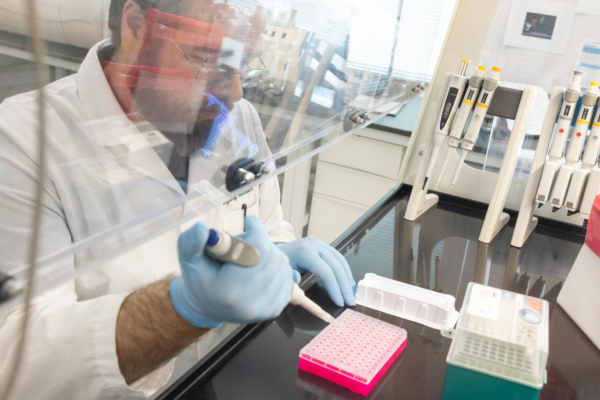

03 Accredited food microbiology testing

For over 20 years, Luminultra has supported the food and beverage industry with fast, accredited microbiology testing from our ISO/IEC 17025 accredited food microbiology lab in Fredericton, NB. Our expert team delivers reliable results for product, water and environmental samples, with services ranging from routine compliance testing to shelf-life studies and contamination troubleshooting. Local. Accredited. Responsive. Everything you need to protect your perishable product, and your brand.

Problem

National labs can be slow, expensive and disconnected from your timelines.

When you’re managing perishable goods, export and complex cold chains, waiting on lab results isn’t an option.

Solution

Luminultra’s accredited food lab for fast, reliable results

Luminultra’s ISO/IEC 17025 accredited lab in Canada delivers fast, expert testing backed by 20+ years of food microbiology experience. We support processors with shelf-life testing, routine compliance, and contamination troubleshooting - with responsive communication and reliable insight. We provide

testing for pathogens, indicator organisms, and spoilage microbes such as E. coli, Salmonella and Listeria. Contact us for our complete catalogue.

Where this matters

- Pathogen monitoring and program verification

- Shelf-life studies and microbial challenge testing

- CFIA, FDA, export and retailer compliance

- Swab and water sample environmental testing

- Rapid response during contamination investigations

Explore more

04 Resolve spoilage challenges

Luminultra helps food producers maintain consistent quality with better insight that enables stronger protocols, improved confidence and reduced risk of spoilage organisms.

Problem

Spoilage and secondary fermentation issues

Some facilities may still face spoilage and secondary fermentation issues even after standard cleaning and “passing” legacy ATP tests. This can result in bloated packaging, reduced shelf life and costly product loss.

Solution

Clearer visibility into contamination risks

Unlike ATP-only tools, A3 measures ATP, ADP, and AMP — providing a fuller picture of surface cleanliness. This added sensitivity helps reveal residues that conventional swabs can miss, giving QA and sanitation teams clearer visibility into potential contamination risks.

Where this matters

- Troubleshooting spoilage or bloating

- Packaging hygiene checks

- CIP validation and optimization

Explore more

05 Manage internal training

Problem

Internal training programs are challenging to keep relevant

nconsistent training and staff turnover weaken sanitation and testing programs. Generic refresher content can lack real-world relevance, and internal development can be time-consuming and expensive.

Solution

Get training help from Luminultra

Luminultra offers practical, tailored training programs and workshops virtually or onsite. Backed by accredited lab microbiologists, experienced processing professionals and food safety experts, we focus on real-world operations: from microbial risk reduction to effective swabbing techniques and group training on new technologies.

Not sure what you need? Let’s figure it out together

Talk to a Luminultra expert and get clear answers, fast.

Build your complete microbial toolkit

Test smarter. Act faster.

Access a full range of solutions designed to bring confidence to the way you work.

From rapid field testing to advanced lab analysis, Luminultra delivers the insight you need to stay ahead of microbial risk. Whether you're using Bugcount® 2nd Generation ATP, Genecount® qPCR, our extensive lab services or our digital platform, Relay™, our solutions put you in control.

What our clients are saying

Real stories of challenges solved with confidence.