Automated ATP monitoring of a tunnel pasteurizer enables improved microbial control with 2nd Generation ATP® testing

Takeaway:

Discover how Luminultra’s BugCount® Guardian helped a prominent beverage production and bottling facility in North America realize the potential for over $200,000 in recovered revenue.

What’s inside:

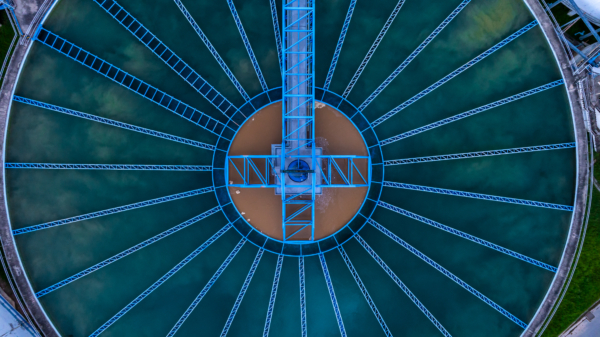

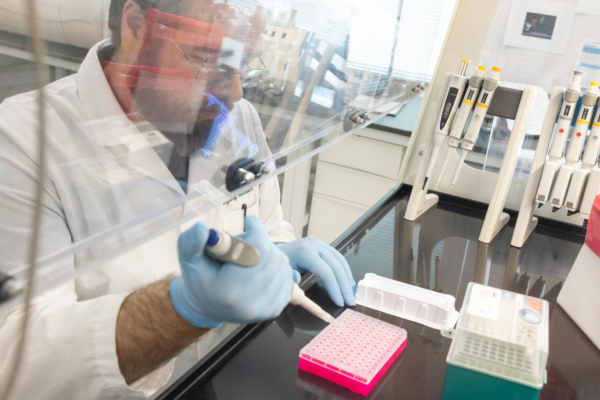

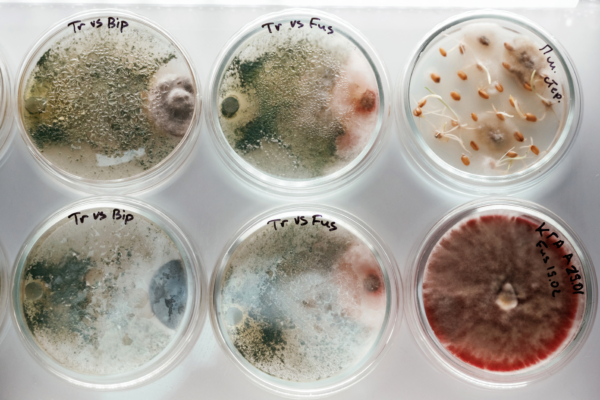

A brewing facility in North America operates a large, state-of-the-art beverage production and bottling plant. The plant utilizes tunnel-style pasteurizers for microbial control of canned beverages ensuring product stability and safety. Elevated microbial levels in the pasteurizer can cause inefficient pasteurization leading to unscheduled production shut-downs, boil-outs or odors on the finished cans that cost production time and lost revenue.

A trial was initiated with Luminultra’s BugCount® Guardian, an online ATP analyzer, which automates the sample collection, testing and reporting of microbiological levels in the pasteurizer.

On three occasions the Guardian data trend demonstrated a consistent increase in ATP; this ATP trend led to swift remedial action through biocide additions which brought the microbial contamination event under control with no loss in production.

Benefits:

Get your copy of the case study to learn more about the benefits achieved during the trial with BugCount® Guardian at the brewing facility, including:

- Simplified and automated microbial process monitoring, with no human resources required for higher throughput testing

- Rapid identification of microbial contamination events

- Optimal biocide treatment

- Reduced rework and downtime

- Enhanced process control and improved product quality

Explore Luminultra resources

Make confident decisions with trusted expertise.

Discover webinars, whitepapers and expert articles focused on microbial control.