Seeing what other tests can’t: How EPCOR used ATP monitoring to strengthen drinking water operations

For drinking water utilities, keeping biologically stable water all the way to the customer’s tap is a daily challenge. Even with strong treatment processes, changes in temperature, flow, or stagnation can trigger microbial regrowth inside the distribution system.

Traditionally, operators have relied on heterotrophic plate counts (HPCs) and disinfectant residuals to flag issues, but these methods often cannot detect early biological changes that are happening, resulting in utilities needing to react only when a problem occurs. Operators are left feeling like they are constantly firefighting issues.

That’s what led EPCOR Water Services to test a new approach.

A 3-year, 5000-sample study on real-world ATP monitoring

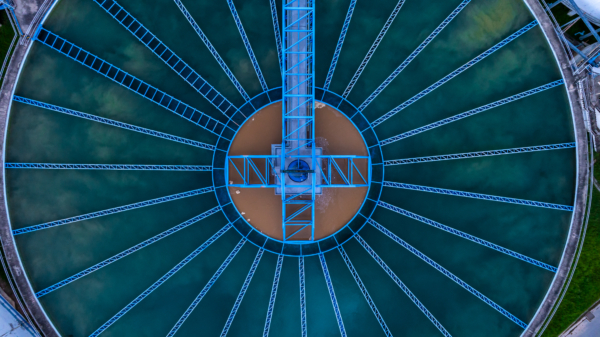

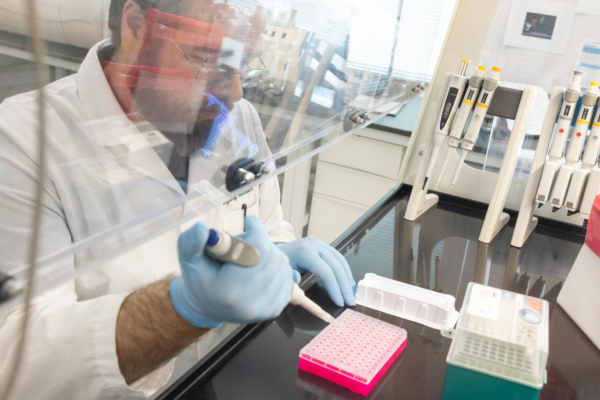

Between 2019 and 2022, EPCOR collected over 5,000 samples from its two drinking water treatment plants and their respective reservoirs, twelve outlying reservoirs, and a 3,900-km chloraminated distribution network. Using Luminultra’s 2nd Generation ATP technology, the team measured total living biomass in minutes instead of days, providing a clearer and faster picture of biological activity across the system.

What they found:

1. ATP revealed what HPC missed

Over 90% of HPC samples were “non-detect,” while ATP consistently showed measurable differences in microbial activity between the treatment plant, reservoirs, and distribution network. ATP’s ability to quickly capture differences in water quality provides operators with more actionable operational guidance opportunities.

2. ATP caught infrastructure issues early

In one outlying reservoir, chlorine and turbidity remained within normal ranges even after an inspection found roof membrane ingress. ATP levels told a different story, rising before visible water-quality shifts occurred. After repairs, ATP readings dropped sharply, proof of successful corrective action.

3. Chemical parameters don’t always predict biology.

The study showed weak correlations between ATP and factors like chlorine, TOC, turbidity, and temperature. In short: good chemical numbers don’t always mean biological stability. With ATP, operators can detect early changes in microbiological activity, serving as an early warning of possible issues.

Setting actionable thresholds

From the dataset, EPCOR established clear ATP thresholds that any chloraminated system can use as a starting point:

| Control zone | ATP (pg/mL) | Recommended response |

| Good Control | < 5 | Maintain routine monitoring |

| Preventative Action | 5 – 10 | Increase sampling / inspect asset |

| Corrective Action | > 10 | Flush, disinfect, or repair |

These values give operators a tangible way to move from reactive to proactive microbial management.

Why it matters for utilities

ATP monitoring doesn’t replace compliance testing, it enhances operational awareness.

It gives you quantifiable, real-time insight into biological stability, helping to:

• Detect regrowth before taste, odor, or chlorine loss appears

• Prioritize maintenance on high-risk assets like outlying reservoirs

• Validate repairs or cleaning work in minutes

• Reduce guesswork between lab cycles

For EPCOR, ATP data has become part of its broader risk and asset management strategy, proving that rapid microbial monitoring can guide smarter operational decisions.

Curious how ATP monitoring could strengthen your own network?

Let’s start a conversation about setting thresholds that fit your system.

Explore Luminultra resources

Make confident decisions with trusted expertise.

Discover webinars, whitepapers and expert articles focused on microbial control.