Webinar on-demand | Beyond compliance: smarter hygiene monitoring for safer food processing

What you’ll learn

This session delivers science-backed insights grounded in real-world processing experience. Led by industry experts with deep knowledge of diagnostics and QA, you’ll walk away with a clear understanding of:

- Why traditional ATP-only hygiene verification can underestimate residual contamination

- How adenylate molecules behave during processing and cleaning

- Where total adenylate testing adds value in high-risk environments

- How rapid hygiene tools fit alongside more precise pathogen and indicator organism testing

- What processors have observed using total adenylate monitoring in practice

Who should watch?

Food processors, QA managers, sanitation leads, food safety professionals and food safety consultants.

As regulatory agencies reduce inspection resources and retailer requirements increase, responsibility for food safety is increasingly shifting onto processors. Bottom line? Relying solely on minimum compliance is no longer sufficient.

This session explores how science-based hygiene verification, particularly total adenylate testing (ATP+ADP+AMP), can help food processors proactively strengthen sanitation programs, food safety culture, reduce risk, and demonstrate leadership regardless of level of regulatory or retail pressure.

Session overview

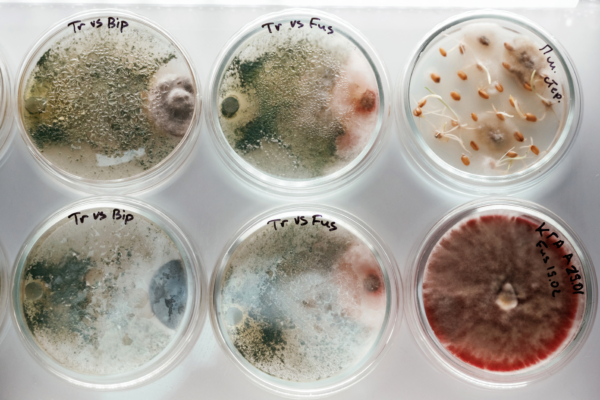

Traditional ATP monitoring has long been used as a rapid indicator of cleanliness. However, research shows that ATP degrades quickly into ADP and AMP during food processing and sanitation – particularly in high moisture, protein-rich environments, leaving residual contamination undetected.

In this session, Dr. Kamarasu joins Luminultra’s Peter Beers to connect the science behind ATP degradation with what it looks like on the plant floor. Together they will share practical observations on how these hygiene verification tools perform under real processing conditions, and what processors gain when they move beyond ATP alone – including improved sanitation visibility, reduced risk, and greater confidence in hygiene programs.

Bringing together scientific evidence, regulatory context, and processor experience, this webinar highlights how global advancements in ATP testing are reshaping hygiene verification, and how these approaches can be applied today across North American food processing facilities.

Meet your presenters

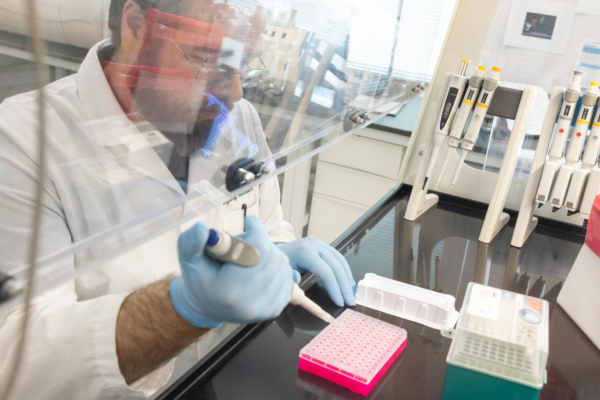

Dr. Pragathi Kamarasu

Food Safety & Vendor Assurance Manager, Raw Seafoods Inc.

Dr. Pragathi Kamarasu brings a rare perspective at the intersection of applied research and real-world food processing. Drawing on her hands-on experience in operational facilities, she has worked with both traditional ATP-only monitoring and total adenylate testing in processing environments.

Peter Beers

Market Sales Leader, Food & Beverage

Peter Beers brings over 13 years of experience in the food and beverage manufacturing industry, with a strong focus on quality, sanitation, and regulatory compliance. His expertise spans audit frameworks such as BRC, SQF, and CFIA, along with hands-on experience in sanitation consulting and industrial hygiene. Peter has supported food and beverage processors across North America in strengthening their food safety and environmental monitoring programs. As part of LuminUltra’s Food and Beverage division, he works closely with manufacturers to improve testing strategies, maintain compliance, and drive continuous improvement in hygiene and product integrity. Known for his practical approach and deep industry knowledge, Peter is committed to helping processors implement effective, science-backed solutions that protect both consumers and brands.

Sarah Cook

Market Development Director, Food & Beverage

Explore Luminultra resources

Make confident decisions with trusted expertise.

Discover webinars, whitepapers and expert articles focused on microbial control.