Summary

This case study outlines the steps taken to address a significant biofilm problem using LuminUltra’s 2nd Generation ATP® monitoring as a guidance tool to optimize treatment.

Symptoms

A microbial audit of a multi-stage electroplating system revealed that the Stage 13, 6.4 cm (2.5 in) diameter PVC water lines were coated with biofilm. Although the biofilm was easily removed mechanically, it resisted chemical dispersant treatment. The ATP-bioburden in the pipe was 3.2 Log10pg tATP/cm2.

Testing

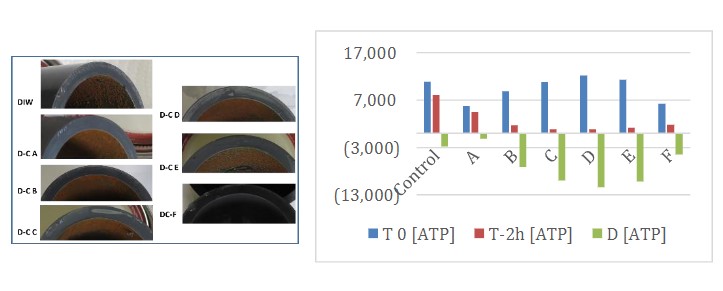

A test plan was designed evaluate the performance of candidate D-C-cleaner (D-C) formulations for their ability to disperse this particularly recalcitrant residue that has developed in the interior walls of polyvinyl chloride (PVC) piping at the electroplating facility. To facilitate shipping, the Stage 13 PVC line was cut into sections, capped, and shipped to BCA for dispersant testing. These sections were then aseptically cut into 10 cm (3.9 in) sections. Test sections were capped and stored until used. Each candidate dispersant (A through F; plus DIW control) was used to treat duplicate sections. Sections were tested before and after a 2h soak period.

Results

Conclusions

The results obtained using the QGO-M and DSA test kits demonstrated how ATP testing can be an effective tool for monitoring biofilms in industrial water systems and for evaluating alternative biofilm removal technologies.