People are often surprised to learn that water is a very important part of oil and gas extraction. Sure, there is an obvious association with water in the term ‘hydro-fracking’, where water is injected underground at high pressure to crack rocks and release huge volumes of tightly-enclosed gas bubbles or oil droplets. But did you know that water is used extensively in conventional oil and gas production too?

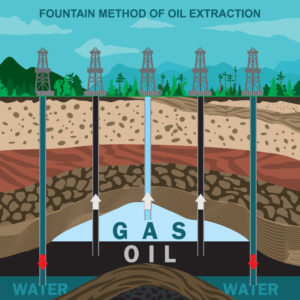

When we drill for oil or gas, we are going deep – more than a kilometer – to tap into pools of compressed, degraded organic matter resulting from ancient plant and animal remains. When we first tap into these pools, we immediately get a release of oil and/or gas but only for a short time before the natural pressure of these reserves is no longer enough to overcome atmospheric pressure. Once the pressure deep underground equalizes with atmospheric pressure, the flow stops – and with it so do the profits. So, innovative engineers figured out a way to use water to recover these remaining trapped oil and gas resources.

When extracting oil and gas, it is now common to drill a series of wells around a central ‘producing’ well. These are known as ‘injection’ wells where water is injected at moderate pressures to ‘push’ the oil and gas towards the producing well, improving the recovery factor.

As you can see, water plays an important role in both conventional and unconventional production processes (including hydro-fracking and Steam-Assisted Gravity Drainage, or SAGD) and, as we know, where water goes microorganisms are sure to follow. If microorganisms are injected ‘downhole’, it is inevitable that some will survive and indeed thrive, resulting in microbial proliferation and biofilm build-up. This leads to well plugging, reduced flow and thus reduced recovery and production. Microbes can also cause issues such as souring (the generation of H2S gas which is both a corrosion and a human health hazard), and Microbially-Influenced Corrosion (MIC), which costs the oil and gas industry billons of dollars per year.

Industry often uses a variety of water treatment methods to remove microorganisms prior to injection as well as biocides to prevent re-growth downhole; but the challenge is knowing what type of biocide to apply and how much is required to effectively treat the water and prevent microbial growth. For this, we require effective monitoring that can be used at the point of treatment. As you may have read on this website, 2nd Generation ATP testing is a proven solution and considered by many as the gold standard in the industry for over 10 years and counting. With its ability to quantify the size of the total microbial population in less than 5 minutes, it is an ideal complement to traditional tests such as Most-Probable Number (MPN), BART, other culture-based analyses, and even next-generation DNA methods which can provide further insight on the microbial community and species abundance. As the old adage goes, “If you don’t measure it, you can’t control it.” Get in front of microbiological contamination through proven, reliable test methods from LuminUltra.

See also:

A Western Canadian oil producer utilized LuminUltra’s Quench-Gone Aqueous (QGA) test kit to perform an audit of its feedwater delivery system. The site acquired water from underground brackish water wells and transported this water through a 5-kilometer pipeline to the site. Water was then stored in a large tank prior to being sent to the process.

Download the case study to see how they achieved their goal of the audit site.